Spin Flash Dryer Design Calculation. 2 Thermal inefficiencies in the utility heat supply.

Calculation of the quantity of water to be evaporated is explained below with a sample calculation.

. Diseño de un secador Flash 2019. HotAirGen_DesignTool 4 Mo This tool calculates the main design parameters of a hot air generator to supply hot air to a flash dryer. Operation typewe will consider either batch.

Process 20 kgh of dry starch. Fluid Electrolyte and Acid-base Balance. In drying of wet solids the following main factors which essentially are used in process design calculation of dryers should be.

Simprosys 21 software package was used to simulate the drying. Heat and mass energy balances in designing a dryer for food applicationsPlease provide feedback on this module by selecting _Like_ or _Dislike_. Let the working pressure be 25 Kgcm2 Vacuum.

Three factors will be considered. 163 Design of Flash Dryers. The results showed that its fuel consumption was 13 Lh and the moisture content.

The flash dryer was fabricated and installed at a Farm in Nigeria and tested under industrial conditions. An Excel-based calculation is used to determine the kiln bed profile and residence time based on specific operating conditions and the kiln configuration followed by a. To the design of extruding and tray-filling equipment for de-watered cakes it is now possible to obtain the maximum benefit of enhanced evaporative rates by using through-air circulation.

Capacity based on 10 moisture wet weight in material fed to dryer and 326 pounds of moisture evaporated per hour for each cubic foot of the volume of the main cylinder. Design calculations establish minimum guidelines and requirements for generating electrical calculations on projects. The hot air generator is basically.

Simprosys 21 software package was used to simulate the drying operation and massheat balances calculated to determine the dryer design variables. Exhaust heat content in convective dryers sensible heating of solids heat losses from dryer body. The column flash drying unit consist of the fan the heater the dryer column and the cyclone.

They are inherently cocurrent dryers with the hottest air contacting the wettest. Continuous process is being started up or shut down the accumulation term is nonzero and the balance 1. Vitamins and Minerals Medicines.

Flash drying is a continuous process with the dryer being either directly or indirectly fired. Design And Fabrication Of A Flash Dryer For The. Of the numerical calculations were partially compared.

In drying of wet solids the following main factors which essentially are used in process design calculation of dryers should be defined in accordance with mass and heat. 1 Thermal inefficiencies in the dryer. As per theory thickness can be derived using the formula T P x R S x E - 06 x P P - design pressure R - Inner dia S - allowable stress E.

2020323This publication presents the design of a flash dryer that can be used to dry cassava cake to produce high quality cassava flour. Mechanism prior to design work is strongly recommended. If the throughput of the dryer is 60 kg of wet product per hour drying it from 55.

Rotary Dryer Detailed Description. Electrical calculations should be made for all SPU projects that. With experimental data and the influence of the fric-tion factor on the pressure gas and particle.

Rotary Dryer from Qingdao Palet Machinery can reduce the biomass material moisture content from 40-55 to below 10 -15 according to. Design and fabrication of a flash dryer for the production of high quality cassava flour.

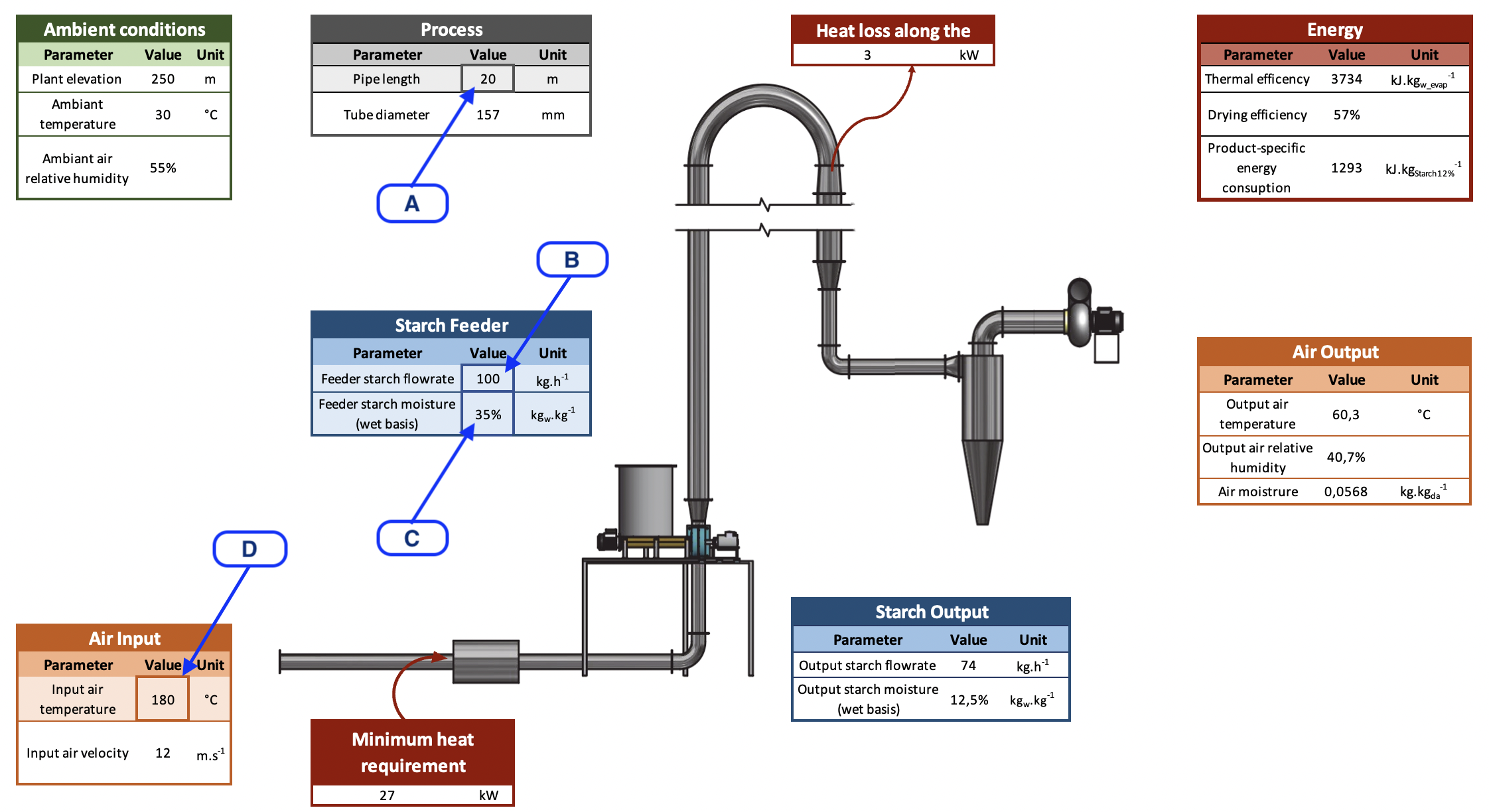

Flash Dryer Design Tools Rtb Scaling Flash Drying

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Springerlink

Pdf 6 Pneumatic And Flash Drying

Flash Dryer Design Tools Rtb Scaling Flash Drying

Pdf Mass And Energy Balance Analysis Of Pneumatic Dryers For Cassava And Development Of Optimization Models To Increase Competitiveness In Nigeria

Pdf 6 Pneumatic And Flash Drying

0 comments

Post a Comment